CGA’s G-4.4 Publication Guides the Safe Design, Operation, and Maintenance of Oxygen Pipeline and Piping Systems

April 22, 2021

Oxygen pipeline systems developed over many decades in the U.S., Canada, various European countries, and in other geographies have shown good and comparable safety records.

CGA G-4.4, Oxygen Pipeline and Piping Systems, describes the principal risks and hazards associated with oxygen systems and the manner in which those hazards can be minimized. This safety standard published by the Compressed Gas Association (CGA), provides design and installation requirements and recommendations for oxygen piping and pipeline systems, and is intended to further the understanding of those engaged in the safe design, operation, and maintenance of gaseous oxygen transmission and distribution systems.

The 6th edition of CGA G-4.4 was published in August 2020. This safety standard has been prepared by specialists in oxygen piping and pipeline systems, representing major oxygen producers in various countries of Europe and North America. Like CGA G-4.1, Cleaning of Equipment for Oxygen Service, CGA G-4.4 is an internationally harmonized publication.

Overview

The scope of safety standard G-4.4 focuses on metal oxygen pipelines, distribution piping systems, and gaseous oxygen piping on an air separation plant external to the coldbox.

Gaseous oxygen is defined as gas that contains greater than 23.5% oxygen by volume, with the remainder of its components being inert. The scope of CGA G-4.4 is limited to gaseous oxygen with a temperature range between –22 °F and 400 °F (–30 °C and 200 °C), pressures up to 3000 psi (21 MPa), and a dew point of –22 °F (–30 °C) or less depending on local conditions.

Although it is possible to safely use oxygen at higher temperatures and/or pressures, such applications are beyond the scope of this publication. In these cases, additional materials testing and/or a risk assessment, as appropriate to the application, should be undertaken.

Oxygen Systems – Mitigating Risks & Hazards

Safety publication CGA G-4.4 describes the principal risks and hazards associated with oxygen systems and the manner in which those hazards can be minimized through good engineering design.

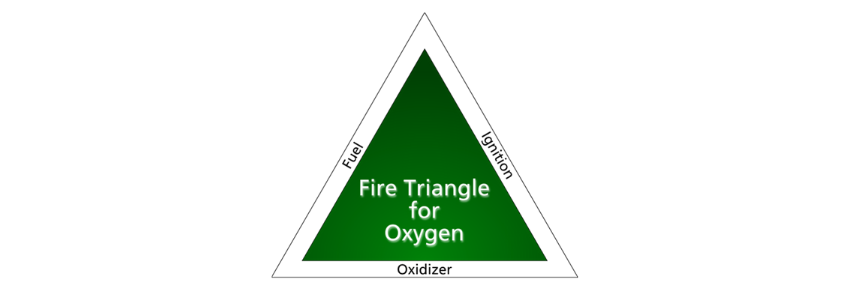

The safe design and operation of an oxygen transmission pipeline or piping system depends on various factors that can influence each other. As demonstrated in the Oxygen Fire Triangle below, in an oxygen system, the 3 main elements required for a fire to occur co-exist: an oxidizer, a fuel, and an ignition source.

In an oxygen system, oxygen itself is the oxidizer and the system fire hazard increases with increasing concentration, pressure, temperature, and flowrate. The fuels in an oxygen system are the materials of construction (metals, nonmetals, and lubricants) or potential contaminants like particulates, oils, or greases, while common ignition sources include particle impact, compression heating, and frictional heating.

Since each leg of the fire triangle is present in an oxygen system to some degree at all times, an oxygen-compatible design is generally one that minimizes the severity of each leg of the fire triangle to a tolerable level.

For example, minimizing the severity of the oxidizer may include reducing the oxygen pressure, temperature, or concentration as practical. Minimizing the severity of the fuels may include ensuring burn-resistant alloys are used in locations where active ignition mechanisms exist. Minimizing the severity of ignition mechanisms may include oxygen service cleaning to reduce particle impact and promoted combustion.

Thus, a safe oxygen piping transmission or distribution system, including all its components, is one that is designed taking into account first and foremost:

- Oxidizer—oxygen conditions of service with respect to fluid purity, composition, gas velocity, pressure, temperature, and dew point

- Fuel—materials of construction, selection of metal and nonmetal components, and burn resistance

- Potential ignition mechanisms—contributing factors that contribute to trigger ignition such as gas velocities and impingement sites that contribute to particle impact ignition, frictional heating, or rapid-opening components such as certain valves

Other factors to be considered include:

- local conditions (for example, seismic zone, soil characteristics)

- applicable piping codes and practices for mechanical design (including pressure rating and wall thickness) and installation

- national laws and regulations that apply to gas transmission pipelines generally and oxygen systems specifically

- standards of cleanliness for oxygen service

- industry codes of practice relating to oxygen systems

What’s New in This Edition

Significant changes made in the 6th edition of CGA G-4.4, Oxygen Pipeline and Piping Systems include:

- Increase in covered temperature ranges for velocity curves

- Clarification of requirements for use of stainless steel in certain applications

- Clarification of requirements for use of exempt materials downstream of a pressure letdown device

- Explanation of requirements for use and cleaning of spiral wound gaskets

- Added requirements for use of plate type check valves downstream of reciprocating compressors

- Elimination of thin stainless steel wool as an absorbing material in inline or vent silencers

- Clarification on the use of grease in valve gearboxes

- Added requirements for HAZOP (hazards and operability study) and risk assessments performed during control station design

- Added requirements for barriers

Publication Details

For more details about this safety standard, the full Table of Contents may be downloaded for free from the CGA G-4.4 publication details page on the CGA portal.

CGA G-4.4, Oxygen Pipeline and Piping Systems, is issued as part of a program of harmonization of industry standards, jointly produced by members of the International Harmonization Council; this safety standard was originally published by the European Industrial Gases Association (EIGA) as EIGA Doc 13, Oxygen Pipeline and Piping Systems.